English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик  简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba

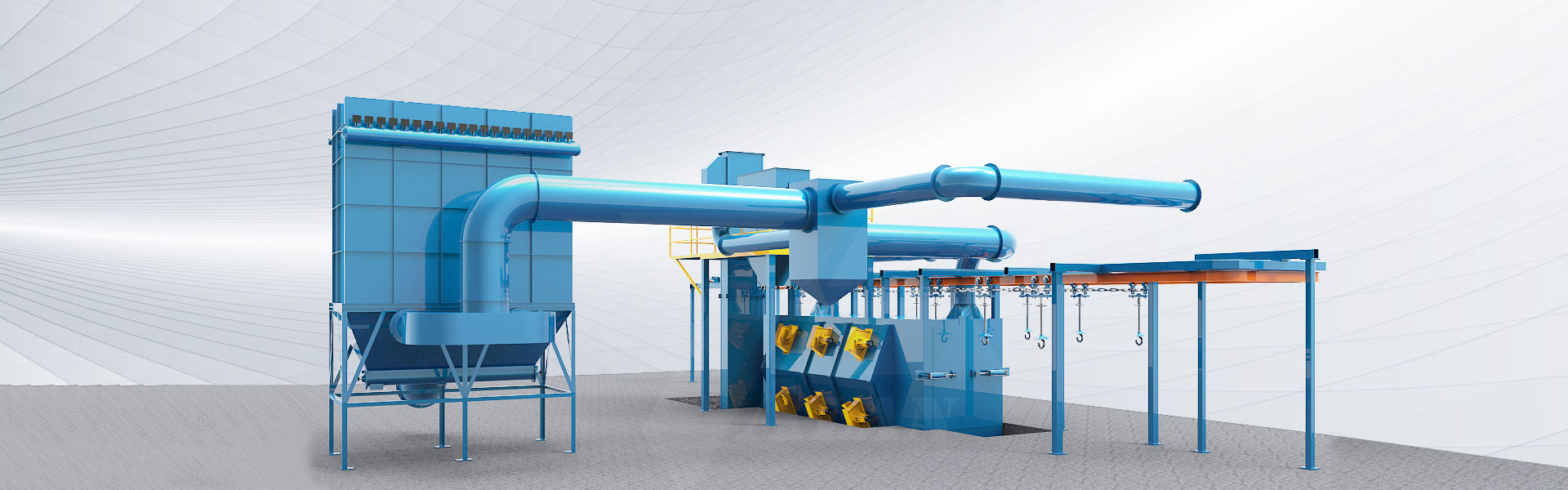

H Beam Steel Plate Shot Blast Cleaning Machine Manufacturers

To fulfill the customers' over-expected pleasure , we've got our strong group to supply our greatest general provider which incorporates promoting, gross sales, planning, production, quality controlling, packing, warehousing and logistics for H Beam Steel Plate Shot Blast Cleaning Machine,h beam shot blasting machine,shot blasting machine,steel shot blasting machine,Q69 H beam sand blasting steel cleaning shot blasting machine, To significantly enhance our company high quality, our firm imports a large number of foreign advanced devices. Welcome clients from your home and overseas to call and inquire!

H Beam Steel Plate Shot Blast Cleaning Machine, You can always find the products and solutions you need to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We're looking forward to work with you for a win-win situation.

Hot Products

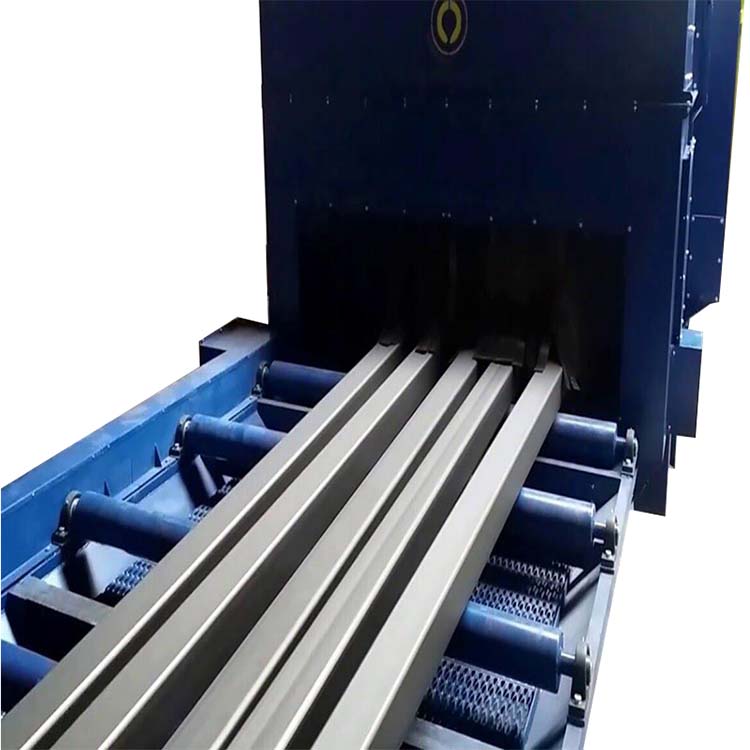

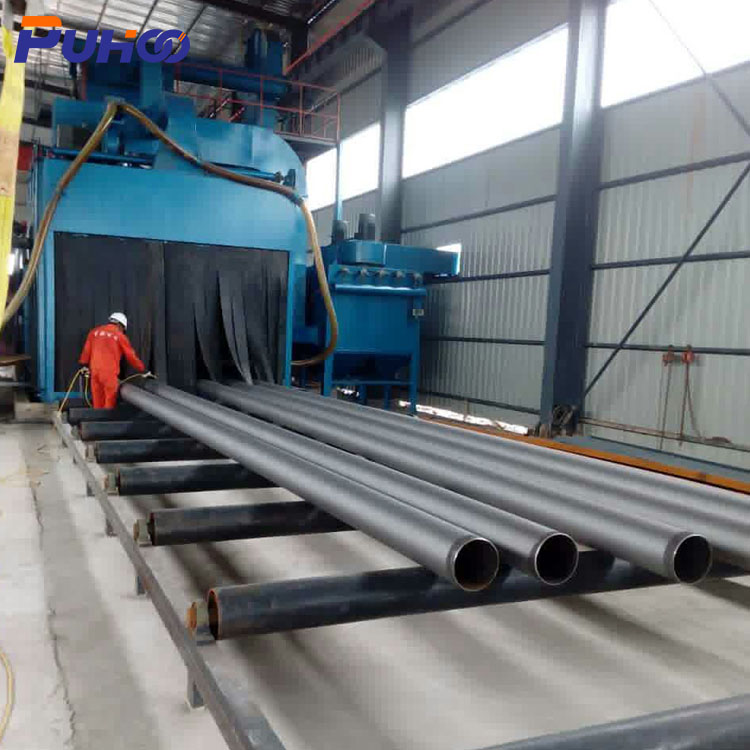

Steel Profiles H Beam Abrator Shot Blasting Machine

Puhua® QG series Steel Profiles H Beam Abrator Shot Blasting Machine Price for surface treatment , wiping up the oxide coating , welding slag, appearing the metallic sheen , increasing the area of the surface , which is in favor of UV. It applies in the line of petroleum& chemical , steel , city centralized heating , centralized drainage etc.Steel Pipe Shot Blasting Machine/Steel Pipe Outer Wall Shot Blast Machines is a combination of clean-steel outer wall of cleaning machine, by blasting to clean the outer surface of the steel pipe, shot by throwing inside to clean surface, so that the surface oxide are rid off. It is used before welding or painting on its outer surface treatment of the pipes.Turntable Type Shot Blasting Machine

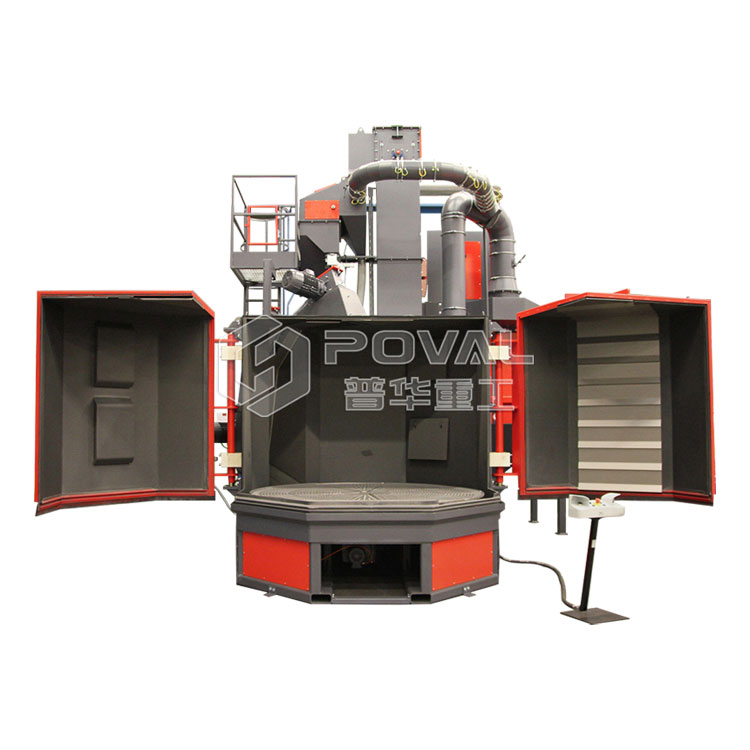

Puhua® Q69 Turntable Type Shot Blasting Machine This machine is mainly used for surface cleaning of casting and forging parts , flat ,thin-wall parts which can’t be collision after heat treatment. It can remove adhering sand, scale, etc attachments on surface of the workpiece , to obtain bright surface with a certain roughness . It can also be used for surface strengthen processing of some gear ,plate spring ,etc.Hook Shot Blasting Machine For Gas Bottle and Cylinders Cleaning

Puhua® Hook Shot Blasting Machine For Gas Bottle and Cylinders Cleaning is mainly used for surface cleaning of casting, structure, non-ferrous and other parts. This series shot blasting machine have many types, such as single hook type, double hook type, lifting type, non-lifting type. It has advantage of non-pit, compact structure, high productivity, etc.Environment Standard Sand Blasting Room Cleaning Equipment Sandblast Cabinet

Puhua® Environment Standard Sand Blasting Room Cleaning Equipment Sandblast Cabinet is widely used in shipbuilding industry, military, and engineering machinery, petrochemical machinery. It could be designed according to customer’s requirements.Liquefied Gas Cylinder Shot Blasting Machine

Puhua® Liquefied Gas Cylinder Shot Blasting Machine is mainly used for surface cleaning of casting, structure, non-ferrous and other parts. This series shot blasting machine have many types, such as single hook type, double hook type, lifting type, non-lifting type. It has advantage of non-pit, compact structure, high productivity, etc.Remote Hook Overhead Hanger Type Shot Blasting Machine for Cleaning Gas Tank

Puhua® Remote Hook Overhead Hanger Type Shot Blasting Machine for Cleaning Gas Tank is mainly used for surface cleaning of casting, structure, non-ferrous and other parts. This series shot blasting machine have many types, such as single hook type, double hook type, lifting type, non-lifting type. It has advantage of non-pit, compact structure, high productivity, etc.