Top Types of Centrifugal Pumps Explained

Centrifugal pumps play a crucial role in various industries, including water treatment, agriculture, and manufacturing. According to a report by Market Research Future, the global centrifugal pump market is projected to reach USD 34.87 billion by 2025, indicating strong growth driven by infrastructure developments and industrial expansion. However, not all centrifugal pumps are designed equally, which leads to inefficiencies if improper types are selected.

Expert John Smith, a renowned figure in pump technology, emphasizes the importance of understanding pump types. He states, "Choosing the right centrifugal pump can significantly enhance system efficiency and reduce operational costs." This highlights the complexity of pump selection, where factors like fluid properties, flow rates, and pressure conditions come into play.

While many believe that all centrifugal pumps function similarly, there are distinct differences that can either optimize performance or lead to failures. Some applications require specific designs, which not only adds to the initial investment but also demands ongoing maintenance efforts. Thus, understanding the top types of centrifugal pumps is vital for engineers and operators alike. Balancing cost and efficiency remains a challenge, inviting professionals to reflect on their choices in pump systems continually.

Types of Centrifugal Pumps: A Comprehensive Overview

Centrifugal pumps are vital in various industries. They move fluids by converting rotational kinetic energy. Understanding the types is essential for effective application.

There are several types of centrifugal pumps. The most common is the standard centrifugal pump. It's reliable and widely used for water transfer. Another type is the submersible pump. This one operates underwater, making it ideal for wells or drainage systems. It's compact but can face clogging issues.

Another interesting type is the vortex pump. This pump can handle solids better than others. However, its efficiency may drop with low flow rates. Each type has unique strengths and weaknesses. Choosing the right one is challenging but crucial for efficiency.

Understanding the Basic Principles of Centrifugal Pump Operation

Centrifugal pumps operate based on a straightforward principle. They utilize a rotating impeller to move liquid. When the impeller spins, it transfers kinetic energy to the fluid. This action increases the fluid’s velocity and pressure. The design allows for a smooth flow, preventing turbulence, which is essential for effective pumping.

A common issue arises during pump operation. Sometimes, air can get trapped in the pump. This phenomenon, known as cavitation, can disrupt flow. It can cause damage if not addressed. Understanding the signs of cavitation is crucial for maintenance. Additionally, proper installation is key. Misalignment can lead to reduced efficiency and increased wear.

In many applications, the choice of pump type matters. Some pumps are better suited for specific tasks. They vary in size, capacity, and materials. Adjusting the pump specifications to fit the needs of the task can improve performance. However, knowing when to upgrade or change pumps can be challenging. It requires careful consideration of the system’s demands.

Comparative Analysis: Single-Stage vs. Multi-Stage Centrifugal Pumps

Centrifugal pumps are widely used in various industries. They can be categorized into single-stage and multi-stage designs. Each design serves distinct applications, with specific advantages and limitations.

Single-stage pumps handle lower pressure and flow rates efficiently. They are often used in domestic water systems and irrigation. According to the Hydraulic Institute, they typically achieve efficiencies of 70% to 85%. However, single-stage pumps may struggle with high-pressure applications. Their construction is simpler, making maintenance less cumbersome. Yet, they do have a limited head capability.

Multi-stage pumps, on the other hand, are engineered for higher pressure requirements. They consist of multiple impellers, which allow them to elevate fluid pressure significantly. These pumps can reach efficiency levels of up to 90% or more. This makes them ideal for uses such as boiler feedwater or high-rise building applications. Unfortunately, they can be more complex to maintain. Each additional stage can add to the wear and tear.

Ultimately, selecting the right pump involves considering specific needs. Knowing when to use a single-stage versus a multi-stage pump is crucial. Industry reports suggest that misapplications are common. Thus, understanding your fluid dynamics is crucial for optimal performance.

Comparative Analysis of Single-Stage vs. Multi-Stage Centrifugal Pumps

This chart compares the performance metrics of Single-Stage and Multi-Stage Centrifugal Pumps, focusing on Flow Rate (GPM) and Max Pressure (PSI). As seen, Single-Stage pumps generally provide a higher flow rate, while Multi-Stage pumps can achieve much higher pressures, making them suitable for different applications.

Applications of Centrifugal Pumps in Different Industries and Sectors

Centrifugal pumps play a critical role across various industries. They are widely used in water management, chemical processing, and agriculture. In water treatment facilities, these pumps efficiently move water and wastewater, ensuring clean supply systems. In the chemical sector, they transport corrosive liquids, while in agriculture, they help irrigate vast fields.

Tips for selecting the right pump: consider the fluid's viscosity, temperature, and required flow rate. Choosing the wrong pump can lead to inefficiencies. In food and beverage industries, hygiene is crucial. Sanitary designs of centrifugal pumps ensure no contamination occurs.

Not all centrifugal pumps are perfect for every application. Some might handle thin liquids well but struggle with heavier fluids. This can lead to unexpected downtime or maintenance issues. In sectors like pharmaceuticals, precise specifications are needed; any deviation can cause serious problems. Always assess the operational environment to avoid mistakes.

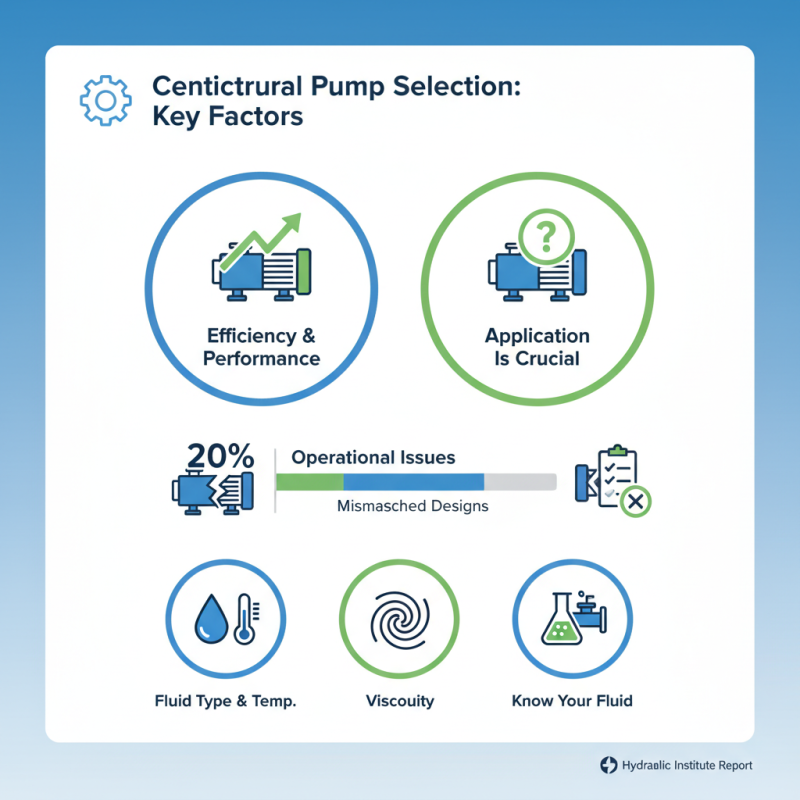

Key Factors Influencing Centrifugal Pump Selection and Efficiency

When selecting a centrifugal pump, key factors significantly impact both efficiency and performance. The specific application is crucial. According to a report from the Hydraulic Institute, nearly 20% of operational issues stem from mismatched pump designs. Knowing your fluid type, temperature, and viscosity plays a vital role in this.

Pump size also matters. Data shows that oversized pumps can lead to inefficiencies, consuming more energy than necessary. A study indicated that around 30% of pumped systems operate at less than optimal conditions. This mismatch can hamper productivity and increase costs. Proper sizing avoids cavitation and prolongs the pump's lifespan.

Lastly, material compatibility is essential. Different fluids can corrode certain materials, leading to maintenance issues. A report by the American Society of Mechanical Engineers highlighted that improper material choice was responsible for over 40% of pump failures. Knowing the operational environment helps mitigate these risks. Adjusting these factors can lead to a noticeable increase in overall efficiency.

Related Posts

-

The Ultimate Guide to Choosing the Right Centrifugal Pump for Your Needs

-

Understanding the Science Behind Centrifugal Pumps in Modern Engineering

-

10 Essential Tips for Choosing the Right Centrifugal Pump for Your Needs

-

Innovative Approaches to Effective Waste Water Treatment for a Sustainable Future

-

2026 Best Waste Water Treatment Plant Innovations and Technologies?

-

Innovative Waste Water Systems Transforming Urban Water Management for Sustainable Development