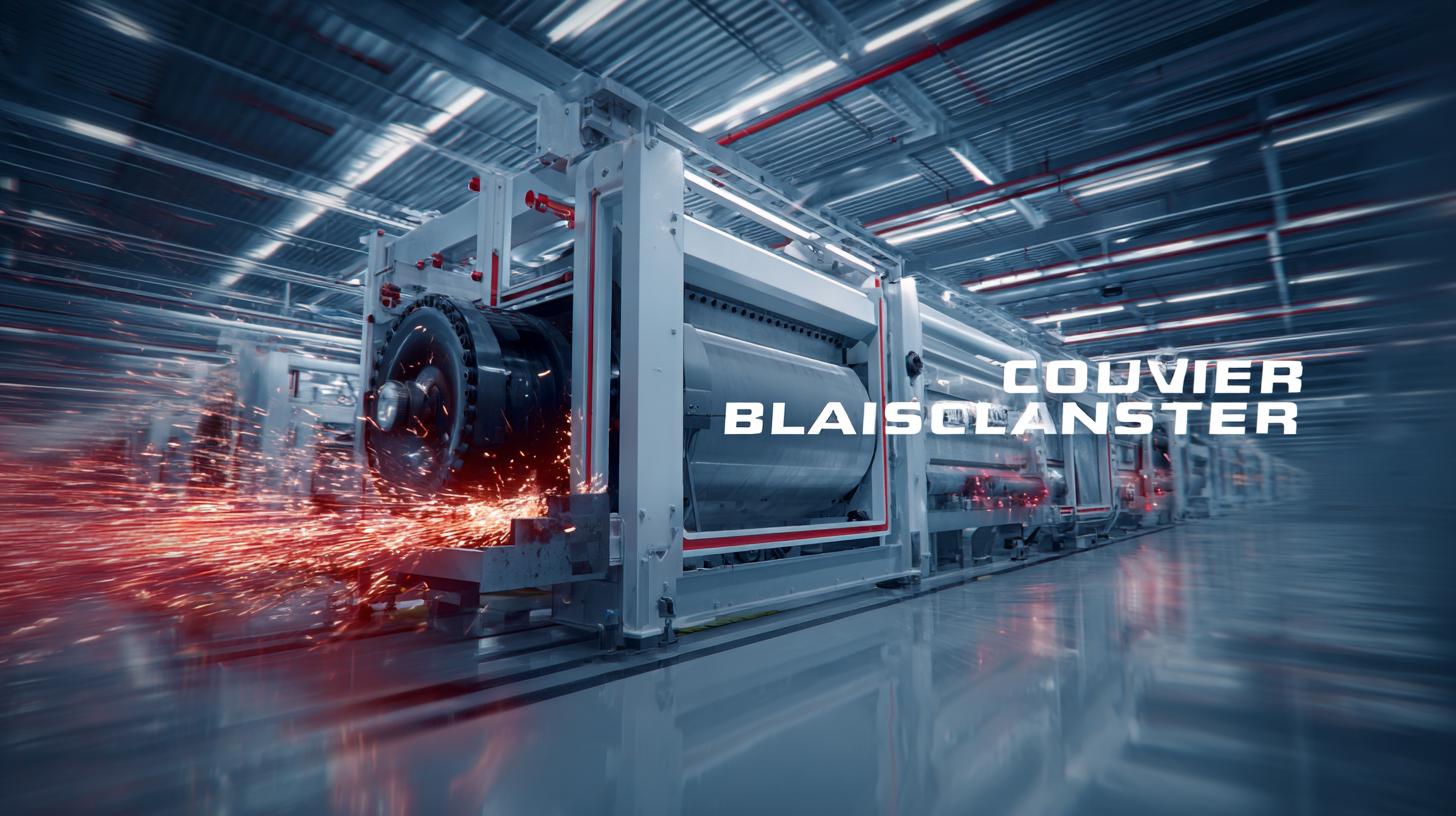

The Future of Roller Conveyor Shot Blasting Machines in Automation and Efficiency

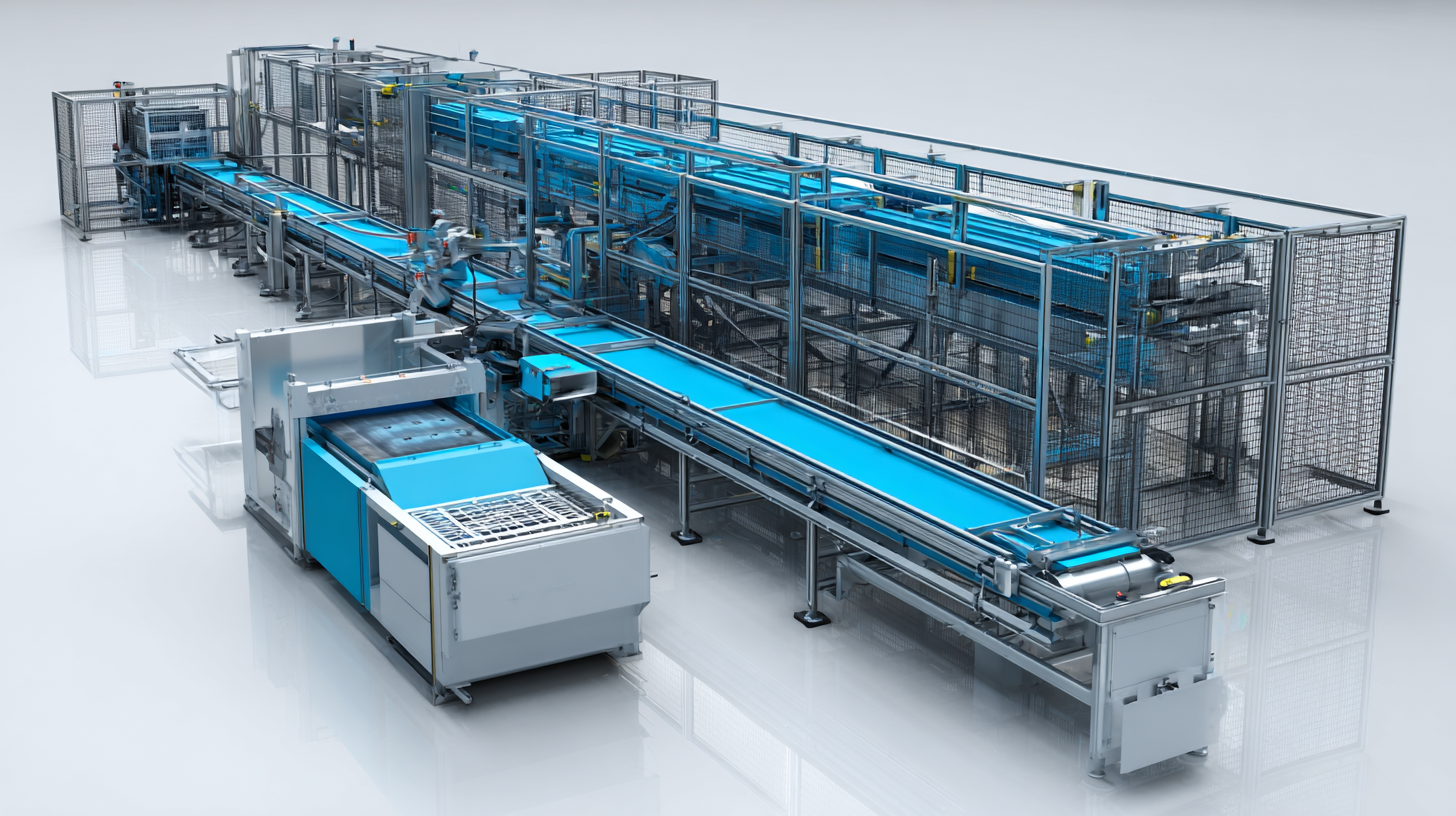

As industries continue to embrace automation and efficiency, the role of specialized machinery becomes increasingly crucial. One of the most significant advancements is the Roller Conveyor Shot Blasting Machine, which enhances surface preparation processes in sectors such as aerospace, automotive, and construction. According to a report by MarketsandMarkets, the global shot blasting machine market is projected to reach $529 million by 2025, driven by the rising demand for quality surface finishing and the need for automated solutions. The Roller Conveyor Shot Blasting Machine stands out due to its ability to continuously treat large volumes of parts, significantly boosting throughput while maintaining high-quality standards.

In this blog, we will explore the future potential of these machines, examining their implications for automation and efficiency in manufacturing processes, and how they can be integrated into modern production lines to meet evolving industry demands.

The Technological Advancements Shaping Roller Conveyor Shot Blasting Machines

The landscape of roller conveyor shot blasting machines is undergoing remarkable transformations driven by technological advancements. As the shot blasting machine market is expected to expand from $1.41 billion in 2025 to $2.22 billion by 2032, which represents a compound annual growth rate (CAGR) of 6.7%, it is clear that automation and efficiency are at the forefront of this evolution. These machines are increasingly powered by cutting-edge technologies that enhance their operational capabilities, thus making them indispensable in various manufacturing sectors.

One of the most significant innovations in this field is the development of advanced blast wheels, specifically designed for forge and foundry applications. For instance, the new COMET HD blast wheel has been engineered to yield a substantial increase in productivity, allowing for cleaner surfaces by effectively removing mill scale, corrosion, and other contaminants. This leap in performance not only reduces downtime but also significantly boosts overall operational efficiency, catering to the growing demand for automated solutions in industrial processes. Such advancements emphasize the pivotal role roller conveyor shot blasting machines play in modern manufacturing environments, ensuring they remain competitive and efficient.

Integrating Automation for Enhanced Efficiency: A Focus on Shot Blasting

The integration of automation in roller conveyor shot blasting machines marks a significant leap toward enhanced efficiency in surface preparation processes. According to a recent report by Market Research Future, the global shot blasting machine market is projected to grow at a CAGR of 5.2% from 2022 to 2030. This growth is largely attributed to the rising demand for automated machinery that can operate continuously and deliver consistent results, reducing manual intervention and minimizing human error.

Advanced automation technologies, such as IoT and AI, have transformed traditional blasting operations into smart systems capable of monitoring performance in real-time. For instance, predictive maintenance enabled by data analytics can enhance machine longevity and reduce downtime by up to 20%, as stated in a study conducted by the International Journal of Advanced Manufacturing Technology. Moreover, automated shot blasting systems can optimize material usage and achieve uniform surface finishes, significantly improving productivity and cost-effectiveness for manufacturers in industries ranging from automotive to aerospace.

Advanced automation technologies, such as IoT and AI, have transformed traditional blasting operations into smart systems capable of monitoring performance in real-time. For instance, predictive maintenance enabled by data analytics can enhance machine longevity and reduce downtime by up to 20%, as stated in a study conducted by the International Journal of Advanced Manufacturing Technology. Moreover, automated shot blasting systems can optimize material usage and achieve uniform surface finishes, significantly improving productivity and cost-effectiveness for manufacturers in industries ranging from automotive to aerospace.

Exploring the Role of Smart Sensors in Modern Shot Blasting Solutions

In the era of Industry 4.0, the integration of smart sensors into roller conveyor shot blasting machines is revolutionizing the landscape of manufacturing. These advanced sensors facilitate real-time monitoring and optimization of the blasting process, significantly enhancing operational efficiency. According to a recent report by MarketsandMarkets, the global market for smart sensors is poised to grow from $7.8 billion in 2020 to $22.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 23.1%. This strong growth underscores the critical importance of smart technology in modern shot blasting solutions.

The implementation of smart sensors allows for precise control over parameters such as blast intensity and cycle time, leading to improved surface finish quality and reduced waste. For instance, sensor data can help operators adjust blasting pressures on-the-fly, leading to energy savings of up to 30% while maintaining performance standards.

**Tip:** For businesses looking to upgrade their shot blasting processes, investing in smart sensor technology can yield substantial long-term savings. Regularly calibrating these sensors can ensure optimal performance and prolong equipment lifespan.

Furthermore, predictive maintenance enabled by these smart systems can prevent costly downtimes. A study from the International Society of Automation indicates that predictive maintenance can reduce maintenance costs by 20% to 25%.

**Tip:** Incorporate data analytics into your maintenance schedule. Analyzing data trends from smart sensors can help anticipate equipment failures before they occur, ensuring continuity in production.

The Future of Roller Conveyor Shot Blasting Machines in Automation and Efficiency - Exploring the Role of Smart Sensors in Modern Shot Blasting Solutions

| Feature |

Description |

Impact on Efficiency |

Role of Smart Sensors |

| Automated Material Handling |

Integration of automated systems for transferring materials through processing stages. |

Increases throughput, reduces handling time, and minimizes manual errors. |

Smart sensors monitor material flow and adjust conveyor speed dynamically. |

| Real-time Monitoring |

Continuous oversight of machine performance and operational parameters. |

Prevents downtime through early detection of issues. |

Sensors provide data for predictive maintenance schedules. |

| Energy Efficiency |

Systems designed to use less energy by optimizing equipment operation. |

Lower energy consumption leads to reduced operational costs. |

Smart sensors adjust energy use based on workload and performance data. |

| Enhanced Safety Features |

Incorporation of safety mechanisms to protect operators and equipment. |

Minimizes accidents and promotes a safer workplace environment. |

Sensors detect human presence and halt operations if necessary. |

| Quality Control |

Automated systems ensure consistent quality in finished products. |

Improved quality leads to fewer defects and higher customer satisfaction. |

Sensors continuously check product specifications against standards. |

Cost-Benefit Analysis: Investing in Automated Shot Blasting Systems

As industries increasingly prioritize efficiency and automation, the shot blasting machine market is poised for significant growth, projected to rise from $1.41 billion in 2025 to $2.22 billion by 2032. This shift highlights the importance of modernizing equipment to enhance operational productivity. Investing in automated shot blasting systems not only streamlines processes but also leads to notable cost savings in the long run.

Tip: When considering an investment in automated systems, perform a thorough cost-benefit analysis. Factor in not just the initial expenditure but also the potential for increased production rates and reduced labor costs. Understanding the full scope of benefits can help justify the investment.

Moreover, with the sand blasting machines market expected to grow at a 4.3% CAGR, it’s clear that the demand for efficient blasting technologies is on the rise. Companies that embrace automation will likely see improved quality and consistency in their output, aligning with industry trends towards sustainable and efficient practices.

Tip: Stay informed about technological advancements in blasting systems. Attending trade shows or webinars can provide insights into the latest innovations that may enhance your operations further.

The Future of Roller Conveyor Shot Blasting Machines in Automation and Efficiency

This chart illustrates the key factors in the cost-benefit analysis of investing in automated roller conveyor shot blasting machines. An initial investment is accompanied by annual maintenance, productivity gains, labor reduction, and improved operational efficiency, highlighting the potential advantages of automation in the shot blasting process.

The Future Trends: Eco-Friendly Practices in Shot Blasting Automation

As industries continue to evolve, the incorporation of eco-friendly practices in shot blasting automation is gaining momentum. Roller conveyor shot blasting machines are adapting to these trends, adopting technologies that reduce energy consumption and waste generation. By utilizing advanced materials and energy-efficient motors, these machines not only enhance operational efficiency but also minimize their environmental footprint. The integration of intelligent controls allows for precise monitoring and optimization of blasting processes, ensuring that resources are used judiciously while maximizing productivity.

Moreover, the push towards sustainability is driving innovations in the recovery and recycling of blasting materials. Modern shot blasting systems now feature closed-loop recycling mechanisms that capture and reuse abrasives, significantly cutting down on material waste. This shift not only supports environmental goals but also reduces operational costs long-term. With ongoing investments in research and development, the future of roller conveyor shot blasting machines promises to align closely with eco-friendly practices, transforming the industry's approach to automation and efficiency while fostering a more sustainable manufacturing landscape.

English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик  简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba

Advanced automation technologies, such as IoT and AI, have transformed traditional blasting operations into smart systems capable of monitoring performance in real-time. For instance, predictive maintenance enabled by data analytics can enhance machine longevity and reduce downtime by up to 20%, as stated in a study conducted by the International Journal of Advanced Manufacturing Technology. Moreover, automated shot blasting systems can optimize material usage and achieve uniform surface finishes, significantly improving productivity and cost-effectiveness for manufacturers in industries ranging from automotive to aerospace.

Advanced automation technologies, such as IoT and AI, have transformed traditional blasting operations into smart systems capable of monitoring performance in real-time. For instance, predictive maintenance enabled by data analytics can enhance machine longevity and reduce downtime by up to 20%, as stated in a study conducted by the International Journal of Advanced Manufacturing Technology. Moreover, automated shot blasting systems can optimize material usage and achieve uniform surface finishes, significantly improving productivity and cost-effectiveness for manufacturers in industries ranging from automotive to aerospace.